Case studies

- Environment

- Challenge

- Solution

- Benefits

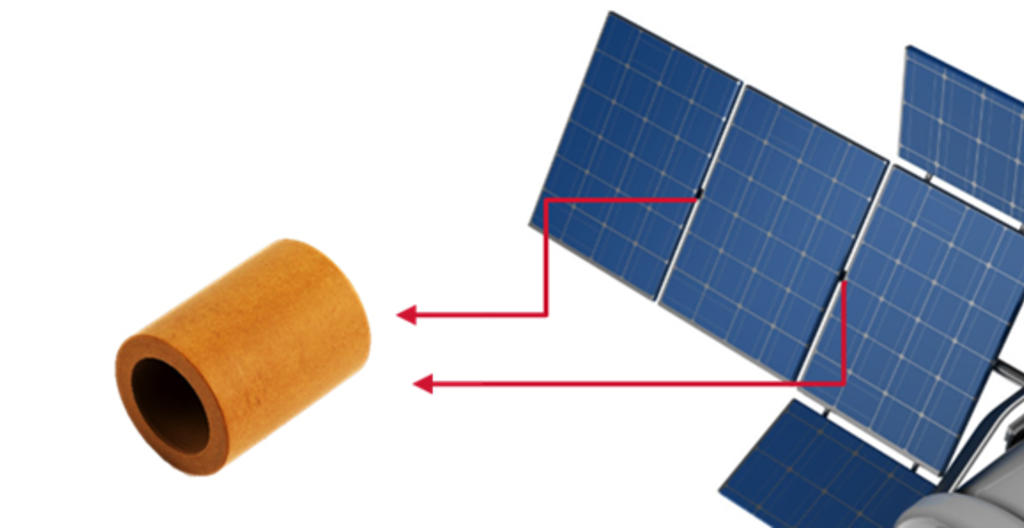

Satellite Solar Panel Array Deployment System

Environment

What provides energy to satellites? A common answer is the sun! Most satellites are equipped with solar panels that convert solar energy into electricity to power the intricate systems onboard. These panels can achieve about 34% efficiency versus the 15 to 20% from most commercial solar panels. When a satellite is launched on a rocket, the solar panel arrays are folded to stay within the space constraints of the payload section. When the satellite reaches its targeted position, the solar panels and antennas are deployed, producing a wingspan of 40 meters! Truly a feat of engineering design since the solar panels need to be compact for launching, expanding and optimum operation.

Challenge

Spacecraft are built so that the solar panels can be pivoted as the spacecraft moves. Thus, they can always stay in the direct path of the light rays no matter how the spacecraft is pointed. The panels need resilient bushings that handle wear and friction in this extreme outer space environment.

Solution

Imagine if the deployment is not successful due to friction, vibration or stiffness issues. This is where another engineering design is valuable. Our Rulon® J bushings are used on the pantograph mechanism joints that are part of the arrays, ensuring deployment is smooth and controlled to guarantee the satellite is working properly for communications or other critical mission. The material minimizes friction and wear and is gentle on the aluminium counter surface.

For the smooth deployment of satellite solar panels, Rulon® polymer materials are stellar for friction, vibration & wear.

For the smooth deployment of satellite solar panels, Rulon® polymer materials are stellar for friction, vibration & wear.

Benefits

-

Low friction

-

Low outgassing

-

Precision machining