298 Search results

Components (35)

This special design seal is also known as a boss seal and is our solution for the hydraulic standard AS5202, which has the best leakage rate and an ease of installation on the fit

This metal face sealing solution allows higher flange lift-off, a lower bolt force requirement and is highly pressure activated.

With 45 years of experience with injection molding diaphragms and PTFE pump components, we have earned the trust of many top OEM for Air Operated Diaphragm (AOD) pump manufacturer

Materials (26)

Our sealing and material experts devote tremendous time and resources to engineering and testing PFAS-Free* solutions that do not compromise on functionality, reliability and prec

Hycomp™ composite materials are made from high temperature thermoset polymers and long carbon or glass fibers for applications requiring high temperature resistance, high mechanic

Consisting of a family of proprietary materials that are composed primarily of polytetrafluoroethylene (PTFE) based resins, the different grades of this high-performance polymer m

Case studies (37)

To control the flow of cryogenic propellants such as liquid oxygen, liquid hydrogen or liquid methane on launch vehicles, cryogenic valves are used within these rockets.

A hot melt adhesive dispensing machine applies hot melt adhesives in controlled patterns and is commonly used in industries such as packaging, electronics, or woodworking.

Liquid chromatography equipment is a widely spread analytical tool used to separate, identify and quantify components in a liquid mixture for purity and content.

White papers (3)

Dating back to the 1970s, Omniseal® PTFE rotary lip seals or rotary shaft seals were introduced to bridge the performance gap between conventional elastomer l

It is a pretty well-known fact that space manufacturers and design engineers spend countless hours testing critical components in their launch vehicle systems such as cryogenic ap

Since the early 1980s, Omniseal Solutions, a global engineering leader relentlessly dedicated to the design and manufacture of precision sealing and material solutions, has focuse

Documents (116)

FAQs, How to guides (6)

With patient care becoming more precise, healthcare technology has been moving to minimally invasive solutions and miniature medical devices.

Our technical team created these how to installation guides to continue supporting our customers through the lifetime of our precision parts.

With patient care becoming more precise, healthcare technology has been moving to minimally invasive solutions and miniature medical devices.

How can you identify and determine authentic polymer materials, particularly for formulas such as those used in Rulon® LR, J, 641 and 123 solutions

Blogs & News articles (49)

Omniseal Solutions, a design engineering and manufacturer of precision seals and materials, has reint

Omniseal Solutions, a design engineering and manufacturer of precision sealing solutions and advanced

Omniseal Solutions, a design engineering and manufacturer of precision sealing solutions and advanced

Omniseal Solutions, a design engineering and manufacturer of precision sealing solutions and advanced

Other site pages (26)

Omniseal Solutions developed the first saddle bearing in Rulon® in the 1940s and the first Air Compressor rotary lip seal in 1984. Discover below the innovative sealing and wear solutions for Compressors, Pumps, Valves, Food Equipment, Semiconductor Equipment, Aluminum Beverage Can making, Heavy Metal Industry, Laser and Plastics processing.

A mixture of tradition and innovation go hand in hand at HTMS, short for High Tech Metal Seals

The story of Hycomp™ is interwoven into a tapestry of innovative people connecting and adding their own “touches”

It seems to be a perfect fit that American Seal & Engineering (ASE) has its founding roots in Connecticut

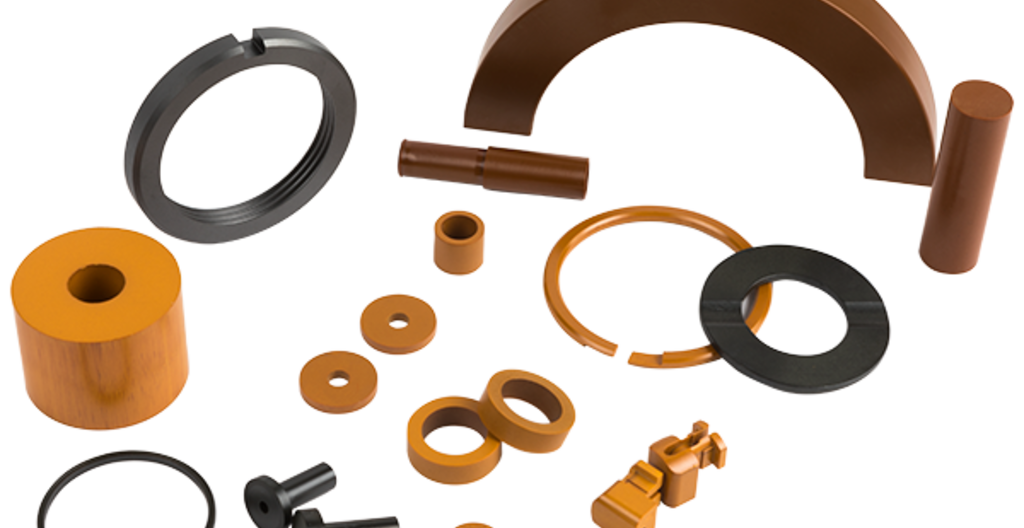

Component Examples

Material Examples

Material Examples

Have a look at some examples of the materials we can formulate and manufacture.