298 Search results

Components (35)

This special design seal is also known as a boss seal and is our solution for the hydraulic standard AS5202, which has the best leakage rate and an ease of installation on the fit

This metal face sealing solution allows higher flange lift-off, a lower bolt force requirement and is highly pressure activated.

With 45 years of experience with injection molding diaphragms and PTFE pump components, we have earned the trust of many top OEM for Air Operated Diaphragm (AOD) pump manufacturer

Materials (26)

Our sealing and material experts devote tremendous time and resources to engineering and testing PFAS-Free* solutions that do not compromise on functionality, reliability and prec

Hycomp™ composite materials are made from high temperature thermoset polymers and long carbon or glass fibers for applications requiring high temperature resistance, high mechanic

Consisting of a family of proprietary materials that are composed primarily of polytetrafluoroethylene (PTFE) based resins, the different grades of this high-performance polymer m

Case studies (37)

To control the flow of cryogenic propellants such as liquid oxygen, liquid hydrogen or liquid methane on launch vehicles, cryogenic valves are used within these rockets.

A hot melt adhesive dispensing machine applies hot melt adhesives in controlled patterns and is commonly used in industries such as packaging, electronics, or woodworking.

Liquid chromatography equipment is a widely spread analytical tool used to separate, identify and quantify components in a liquid mixture for purity and content.

White papers (3)

Dating back to the 1970s, Omniseal® PTFE rotary lip seals or rotary shaft seals were introduced to bridge the performance gap between conventional elastomer l

It is a pretty well-known fact that space manufacturers and design engineers spend countless hours testing critical components in their launch vehicle systems such as cryogenic ap

Since the early 1980s, Omniseal Solutions, a global engineering leader relentlessly dedicated to the design and manufacture of precision sealing and material solutions, has focuse

Documents (116)

FAQs, How to guides (6)

Design engineering the right precision solution in the form of seals or material components is instrumental to whether your core systems run ... or not.

Quality, certification, and processing. These are just a few of the key points that are important to consider when choosing a seal manufacturer.

Blogs & News articles (49)

Omniseal Solutions, a design engineering and manufacturer of precision seals and materials, has reint

Omniseal Solutions, a design engineering and manufacturer of precision sealing solutions and advanced

Omniseal Solutions, a design engineering and manufacturer of precision sealing solutions and advanced

Omniseal Solutions, a design engineering and manufacturer of precision sealing solutions and advanced

Other site pages (26)

As you may have heard, the Italian office has existed for more than 20 years. It’s a completely unique case. In some countries, we only have salespeople working alone. In Italy, Saint-Gobain kept the complete structure of the Italian distributor acquired many years ago by Furon, before becoming Omniseal Solutions.

With some exceptions, like Luciano, many people have changed over the years. Personally, I have worked in the office for almost 13 years! The size of the team, however, remained the same size (approx. 10 people). Also, we have always lived as a kind of separate small entity, both compared to the Omniseal Solutions sites and compared to the Italian Saint-Gobain entity that we belong to. Kind of like the satellites we work with and that speaks with our space applications - connected with the earth but moving independently.

Somewhere in the 90s, we received a big claim from a very well-known F1 team. They were facing problems with our seals and one of the biggest issues was debris in the cavity of the seal. Since it was an important account to Kontich and the opportunity was there to become even bigger and recognized in the F1 world, we couldn’t ignore their comments. One of our responses was to build a cleanroom. This is a temperature, humidity, and cleanliness-controlled room.

One machine, one table, one microscope … that’s how it all started. With a lot of agility, knowledge, and drive, our cleanroom became well known in the F1 world. When needed, we put in a lot of overtime to help the customers out, people went on airplanes with seals in their hand luggage, we were invited to the F1 circuit, lots of prototyping (with little more than a sketch to start from), and “first time ever” situations … the golden times of the F1 within SG.

Caring for the local and global community doesn't just make business sense, it is a privilege, one which the employees of Omniseal Solutions enjoy. In this article, read about how 37 members of our team in Belgium have become foster parents to underprivileged communities in Togo. The rewards have gone both ways, enriching the lives of the villagers, but also giving the team a sense of pride, accomplishment and a unique view on the world we live in.

Omniseal Solutions provides components and materials for Life Science applications that test purity in pharmaceuticals, diagnose disease to provide vital treatment, surgical devices for lifesaving procedures and home health to better life such as portable oxygen concentrators or diabetic monitoring.

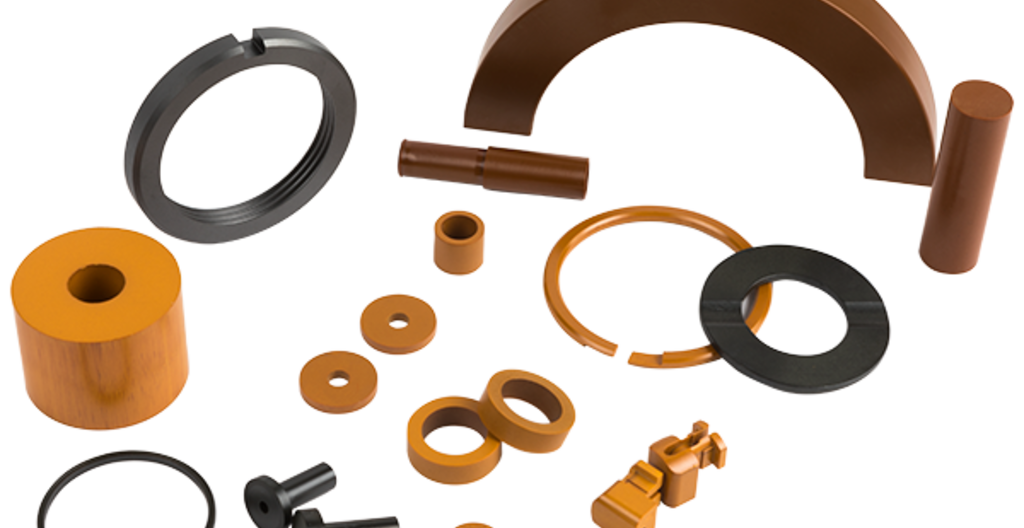

Component Examples

Material Examples

Material Examples

Have a look at some examples of the materials we can formulate and manufacture.