Case studies

- Environment

- Challenge

- Solution

- Benefits

- Specifications

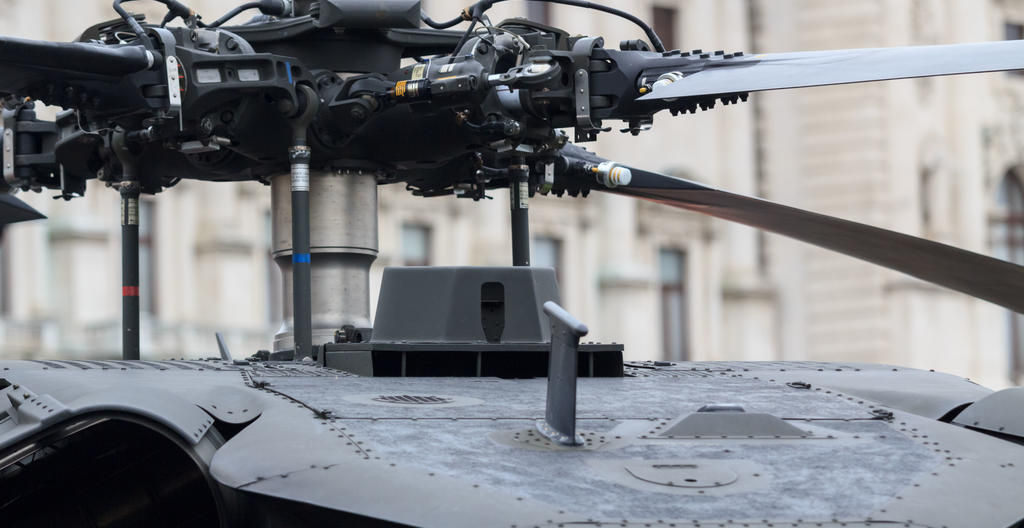

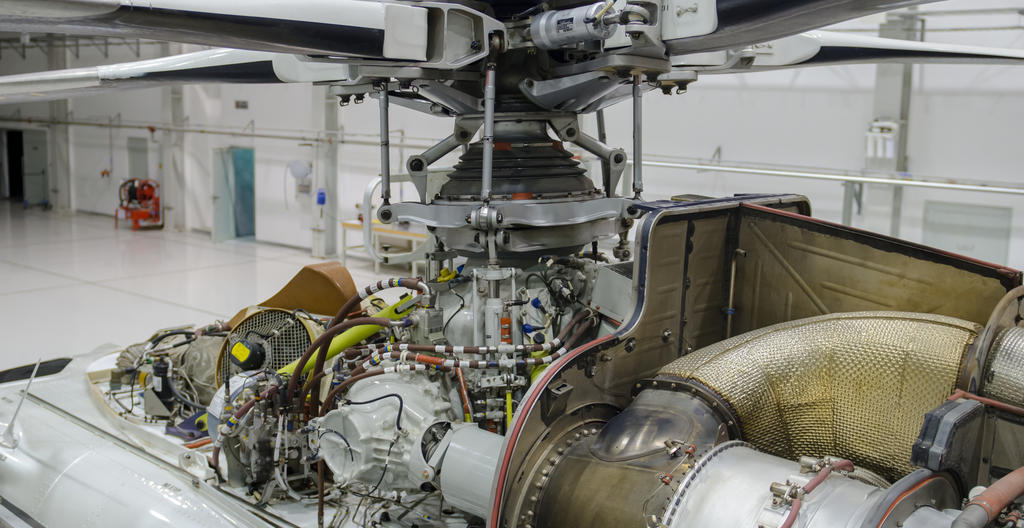

Helicopter Main Gearbox

Environment

How would a helicopter main gearbox (MGB) successfully function without the proper sealing solution? Rotary lip seals are widely used to seal the oil lubricant within the gearbox and protect it from leaking out at where the shaft enters and exits the gearbox.

Challenge

A number of significant helicopter accidents are caused by a loss of lubrication as friction is increased between components, leading to a mechanical failure of gearbox components.

The main gearbox, also known as a transmission, is a critical part in a helicopter’s airworthiness and safety because it is responsible for reducing high input speed generated from engines and providing appropriate torque to main rotors and other accessory systems.

Solution

Our customer trusts our polymer lip seals due to their low coefficient of friction, low wear rate at high rotary speed, high thermal resistance, and ability to run dry if loss of lubrication should occur.

Along with these mechanical properties, our customer finds that the lightness and compactness of our lip seals and their ability to prevent dust and pollutants to enter the gearbox and ruin the gears are also major advantages for using our rotary lip seals.

Protecting the skies!

Protecting the skies!

Benefits

-

Acts as a rotary seal between gearbox and exterior to retain oil in contact with a high speed rotating shaft

-

Wiper design prevents dust and particles from coming inside the gearbox

-

Adjusts for hardware misalignment, wearing on sealing material is minimal

Specifications

|

Solution |

|

|

Area |

|

|

Material |

|

|

Precision Part |

|

|

Technical Details |

|