News

Meldin® 7001 Material Qualified for Electric Harness in Major Jet Engine Program

Aviation Solution

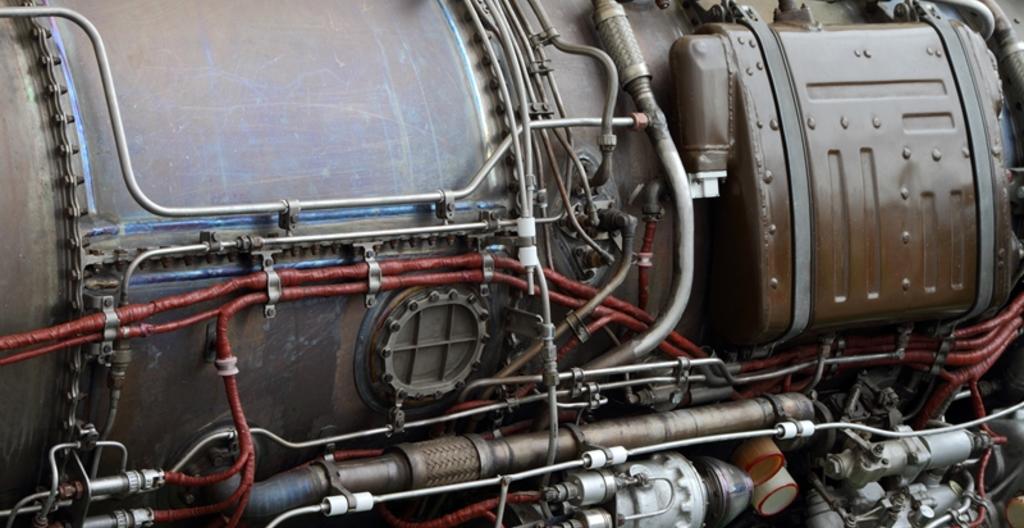

Omniseal Solutions' Meldin® 7001 virgin polyimide solution has been qualified as a precision fixing element on electric (wire) harnesses for a well-known jet engine program because it reduces global cost of installation and provides customers lifetime confidence. Developed and produced at their Bristol, Rhode Island, site since the early 2000s, the Meldin® polyimide solution is used for applications in a wide range of temperatures from -196°C to 316°C continuously and up to 482°C intermittently (from -321°F to 600°F and intermittently to 900°F). It is often specified for structural critical parts in aviation and high-purity critical parts in electronics and semiconductor fields.

Careful attention to electric systems on modern jet engines has been growing; one reason is due to the high quantity of electric wires present in jet engines, including those on pneumatically driven aircraft. The electric wires become an issue for aviation manufacturers who need them to be robust enough to resist the harsh conditions of the engine environment such as high temperature, presence of harsh chemicals and moisture, vibrations and sharp edges. A second difficulty is fixing the wires properly to the engine structure. This is where an electric harness comes in handy since it binds the wires and fixing element together so they are secure.

Click Print button to get full press release!