Case studies

- Environment

- Challenge

- Solution

- Benefits

- Specifications

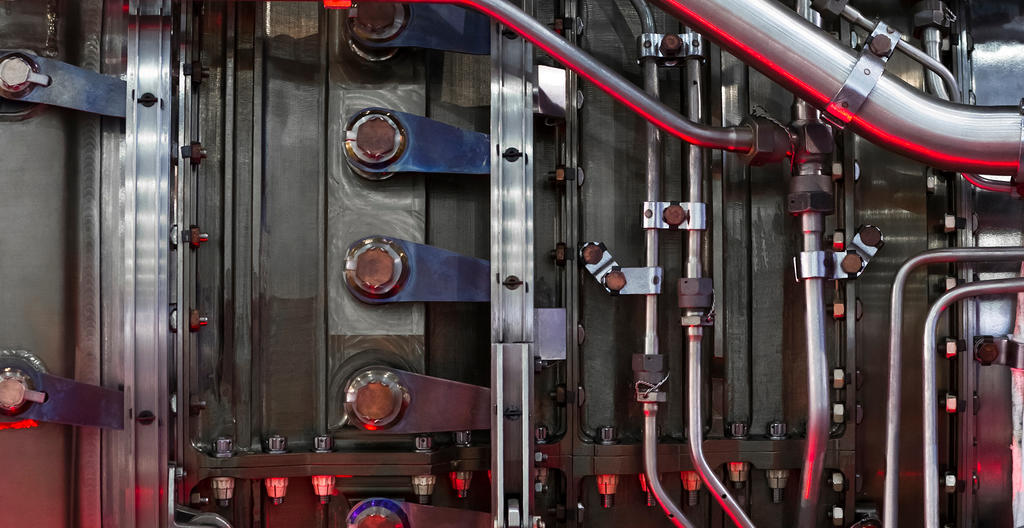

Compressor Variable Stator Vane Bushings

Environment

At different speed regimes in the jet engine, the airflow in the compressor is regulated by variable stator vanes (VSV), which are generally located at the initial stages of the high pressure compressor. This area experiences relatively high pressure and high temperature that progressively increases with modern engine performances.

Challenge

Due to high vibration and high loads, variable stator vane bushings are subject to considerable strain, high temperature (up to 370°C / 700°F), and atmospheric oxidation. Since the bushings are also utilized as a sealing function, these critical parts are responsible for avoiding too much pressure loss from the compressor and as a result, strict tolerances are required.

Solution

Omniseal Solutions' Meldin® 7000 polyimide is one of the very few materials with self-lubricating properties, mechanical strength, and machinability that makes this solution suited for the variable stator vane application. The polyimide’s thermo-oxidative stability also allows the material to sustain the hot air environment.

Additionally, tight tolerances can be achieved in order to allow good airflow restriction for improved system efficiency. This Meldin® material is a proven aviation solution, having been qualified by several jet engine OEMs and flying successfully in commercial aircraft for decades.

High temperature & high pressure are controlled

High temperature & high pressure are controlled

Benefits

-

Self-lubricating properties preserve hardware and improve durability without a lubrication system

-

High temperature resistance under oxidative atmosphere for better durability

Specifications

|

Solution |

|

|

Area |

|

|

Material |

|

|

Precision part |

|

|

Technical details |

|